Electric Motors

Coming Through In The Clutch

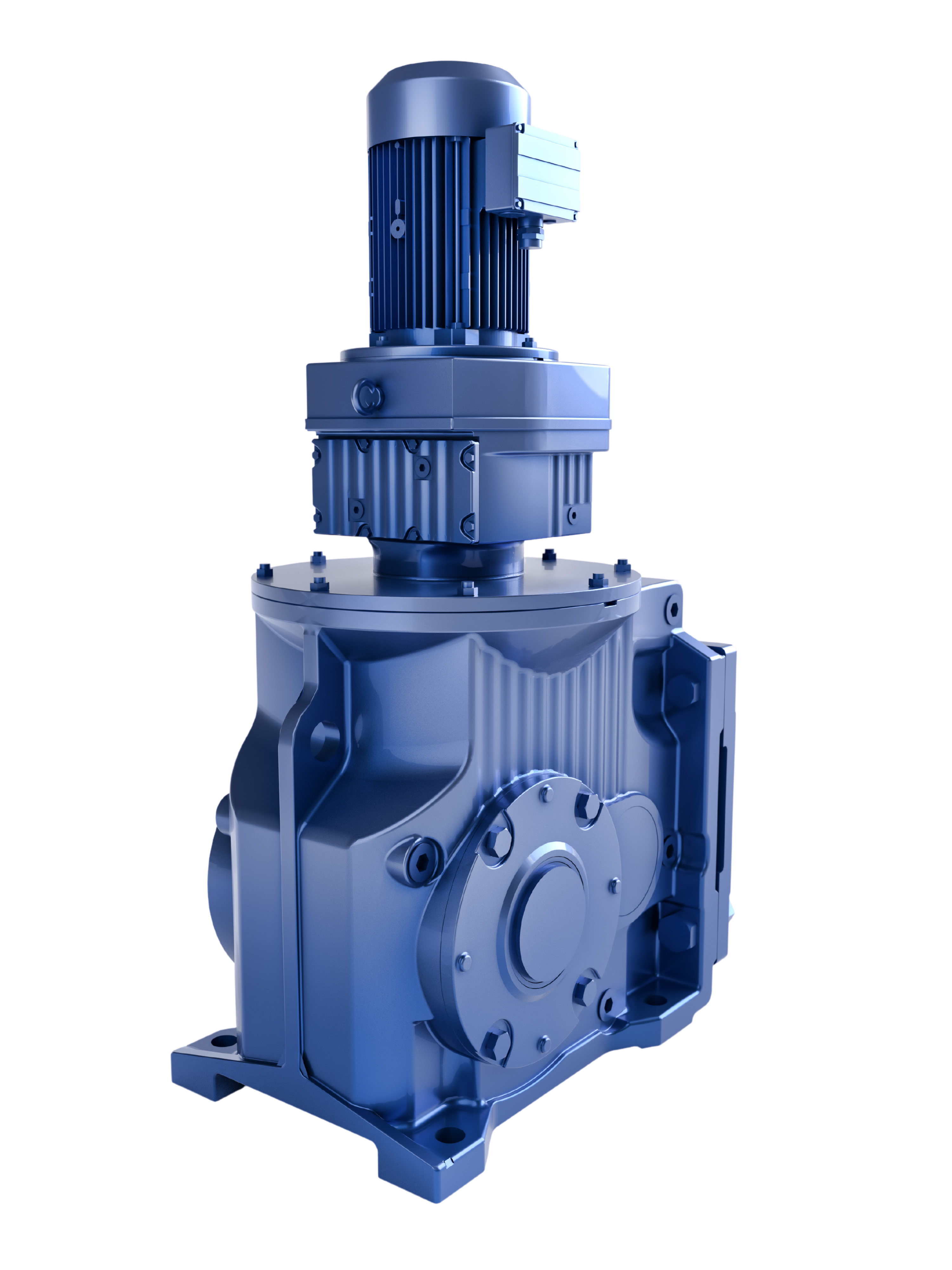

Electric motor repair has been the backbone of our company since 1931. Over time we’ve fostered close relationships as an authorized service center for most major manufacturers of AC/DC motors, gearboxes & clutches. This allowed us to build a network of large inventories, offer the best prices, and provide superior service.

Services That’ll AMP You Up

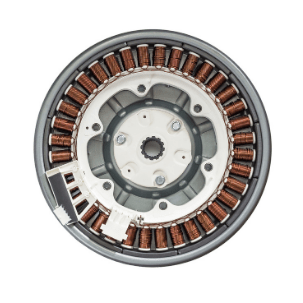

Our AC/DC Motor Techs execute a strict regiment of disassembly, load testing, balancing, assembly, and quality control checks before being stamped with our seal of approval. Yet this time-tested process does not slow us down. We offer same-day & overnight repair.

- On-site or shop repair on all AC/DC makes & models

- Authorized UL (re)certification

- Routine checks for AC core & core loss

- On-site or shop repair on welding equipment

- Complete servicing for air or water-cooled clutches

- Repair pump motors & hazardous heavy-duty motors

- Reports & repair estimates for your records

- Factory authorized motor warranty repair

- Rewind of AC/DC motors to EASA specifications

- 5000 HP – 4160 volt AC motors

- AC slip ring rotors

- Formed coil & mush-coil (random wound)

- Large synchronous motors

- DC armatures & fields

Advanced Motor Diagnostics

Know before they go. Our Advanced Motor Diagnostics Service is an advancement on PDMA services, utilizing both motor circuit analysis & electrical signature analysis providing data on key metrics to fix or prevent motor downtime.

- This predictive maintenance program can find or prevent:

- Turn-to-turn

- Coil-to-coil

- Phase-to-phase

- Open phases

- Burned/contaminated windings

- Poor connections

- Broken/cracked rotor bars

- Voids

- Rotor eccentricity

- Grounded windings

- Cable faults

- Non-destructive & portable, continuous operation or offline testing diagnostics for:

- AC induction motors

- DC motors

- Generators

- Wound rotor motors

- Synchronous motors

- Network of specialty motor partners:

- Servos

- Steppers

- Spindles

Dynamic Balancing

Our experienced Pros can service equipment with precision & speed using dynamic balancing technologies. Deposit build-up, distortion as well as general wear & tear can wreak havoc on any motor. The cost of avoiding this critical maintenance is incalculable, saving on repairs, parts & downtime.

- We balance all rotating equipment of major manufacturers for:

- Blowers

- Mixers

- Fans

- Rotors

- Armatures

- Combine Blades

- Specialty equipment

- Production equipment

- Service & documentation providing data with a goal to:

- Increase machine life

- Boost product quality

- Reduce down-time

- Improve energy use

- Minimize vibration

- Reduce noise

- Ease structural stresses

- Improve operator fatigue

Motor & Accessory Brands We Service & Sell

Motors

Motors

Reducers

General Accessories

Spark-Up A Conversation

Larry Klevorn – Manager

314.638.9641 x.224

[email protected]

Nick Schneeberger – Assistant Manager

314.638.9641 x.230

[email protected]

Repair: Ship To

4250 Hoffmeister Ave

St. Louis, MO 63125

Competencies

- Motor repair

- Motor rewind

- Motor balancing

- Equipment diagnostics

- Pump repairs

- Fan repairs

- Gearbox repairs

- So much more

Service Areas

- Missouri

- Illinois

- Arkansas

- Kansas

- Kentucky

- Tennessee

- Indiana